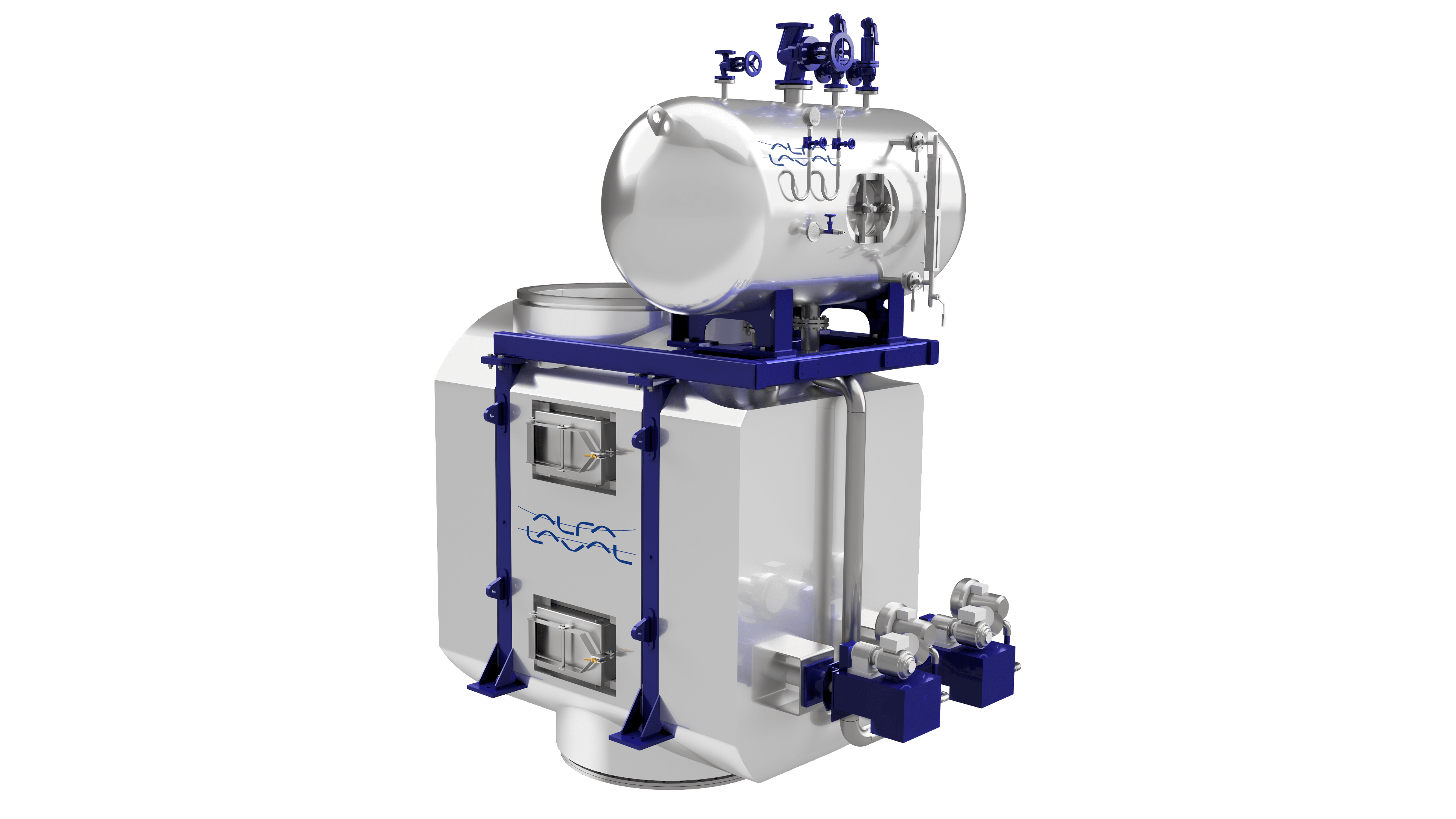

Aalborg XWi

El Alfa Laval Aalborg XWi es una caldera de gases de escape para recuperación de calor residual del motor. Sus tambores de vapor superiores permiten circulación natural, eliminando bombas, y pueden incluir calefacción eléctrica. La superficie de calentamiento tiene un evaporador de tubos de agua para vapor de alta presión, con secciones opcionales como economizador, sobrecalentador, evaporador de baja presión y agua caliente para mayor eficiencia.

Alfa Laval Aalborg XWi – caldera de gases de escape con circulación natural

- Potencial máximo de recuperación de calor para reducción de CO₂ a bordo

- Operación simple, fiable y eficiente con circulación natural

- Sin consumo de energía ni costes de mantenimiento para las bombas

- Unidad compacta, instalación sencilla y responsabilidad claramente definida

- Posible integración de generación de vapor eléctrica mientras el motor no está en funcionamiento

La caldera Aalborg XWi con circulación natural ofrece ahorros en los sistemas de recuperación de calor residual y elimina todos los problemas típicos asociados a los sistemas de circulación forzada, como cavitación, golpes de ariete y pérdidas operativas y de mantenimiento.

El tambor de la caldera Aalborg XWi puede integrarse con elementos de calefacción eléctrica para aprovechar la conexión a la red eléctrica en puerto y generar vapor. La configuración de la superficie de calentamiento es flexible. La eficiencia energética del sistema puede aumentarse añadiendo secciones de tubos para el precalentamiento y/o sobrecalentamiento del agua de alimentación, así como para la generación de agua caliente. El diseño de la superficie de calentamiento puede adaptarse al motor y a las condiciones de operación reales, manteniendo una velocidad de gases de escape suficiente para lograr los mejores efectos de autolimpieza dentro de los límites de diseño.

Recuperación máxima de calor residual a niveles de presión múltiple en el Icon of the Seas

Cómo funciona

La circulación natural se refiere a la capacidad de un fluido en un sistema para circular por medio de la gravedad y las diferencias de densidad. En el Aalborg XWi, la circulación comienza de forma natural cuando el motor arranca y termina de forma natural cuando el motor se detiene. El agua permanece dentro de los tubos de la superficie de calentamiento, lo que previene el riesgo de incendio por hollín y minimiza la pérdida de energía, ya que no hay circulación innecesaria durante la parada.

Como el agua solo circula por el Aalborg XWi cuando el motor está en funcionamiento, no se pierde calor hacia el aire frío que atraviesa la caldera cuando el motor está detenido. Esto significa un menor uso de la caldera auxiliar, con reducción de costos de combustible y emisiones.

Cuando la circulación se detiene, el agua llena los tubos de la caldera. Esto minimiza el riesgo de incendios por hollín, que pueden ocurrir con la circulación forzada. En los sistemas de circulación forzada, la disposición típica del sistema y los cambios súbitos en la carga del motor a menudo provocan problemas en la circulación del agua, como cavitación de la bomba, que puede causar un incendio por hollín dentro del sistema.

Service

Ofrecemos asistencia completa para nuestros sistemas de calderas de vapor para cruceros y transbordadores. Nuestra asistencia cubre todo su ciclo de vida, desde el diseño, la instalación y la puesta en marcha, pasando por la garantía y durante toda la vida útil.

No podemos predecir el futuro, pero los contratos de servicio de Alfa Laval pueden hacerlo menos incierto. Un contrato de servicio de duración determinada hace que la planificación operativa y las previsiones de costes sean más seguras. Una estrategia de mantenimiento bien diseñada ofrece un control transparente de los costes y garantiza el rendimiento, lo que prolonga la vida útil de su equipo y reduce sus costes operativos totales. El mantenimiento experto no solo mejora el rendimiento de su equipo Alfa Laval, sino que también le ayuda a sacar más partido al equipo que lo rodea.