Alfa Laval Compabloc solucionó el problema de las incrustaciones

Queensland Alumina reemplazó una unidad de carcasa y tubo con una unidad condensadora Alfa Laval Compabloc completamente soldada para reducir los costos de mantenimiento. Utilizando solo una cuarta parte del espacio de la antigua instalación de carcasa y tubos, el Compabloc resolvió problemas severos de corrosión e incrustaciones, lo que resultó en una reducción significativa del costo de servicio.

FECHA 2025-05-12Process Plant

The Queensland Alumina plant at Gladstone produces 3.7 million tonnes of alumina annually using the Bayer process, the thermal process based on the solubility of alumina in caustic liquor.

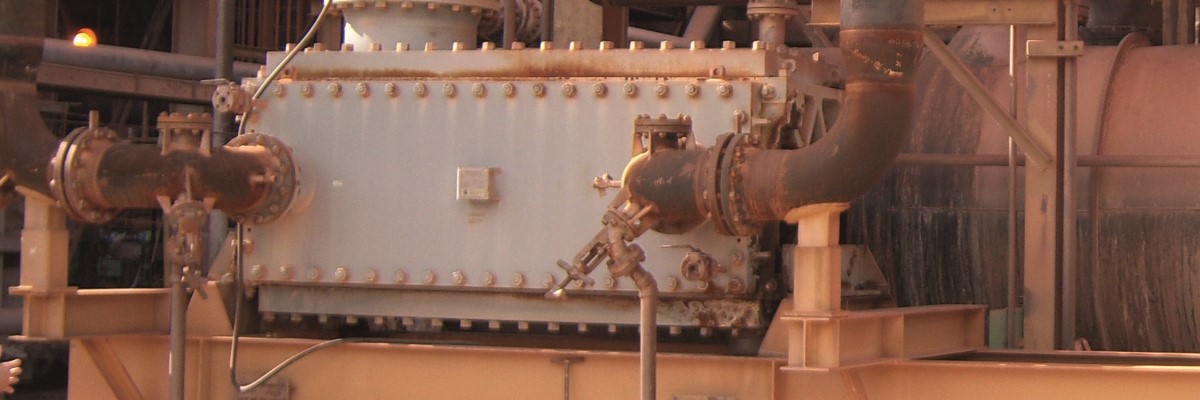

Heat exchangers are required for a broad spectrum of duties in the process of heating and cooling the circulating liquor stream. The Compabloc replaced the original carbon steel shell-and-tube heat exchanger in the precipitation area, where it is heating incoming process water with final flash vapour at 29 kPa abs.

The compact, fully welded Compabloc heat exchanger is designed to operate with a wide range of aggressive media and at high temperatures and pressures.

Looking for a new solution

As for many process industries using heat exchangers, the most important requirements for Queensland Alumina are:

- High thermal efficiency

- Low fouling and scaling

- Minimal space requirements

- Design flexibility

- Ease of installation

- Minimal maintenance