Proceso de aminas

Removing high content of hydrogen sulfide from refinery gas streams by using amine gas treating processes calls for highly reliable, low-maintenance equipment. Alfa Laval Compabloc heat exchangers in corrosion free materials deliver energy efficiency and maximize uptime by minimizing fouling tendencies in refineries world-wide.

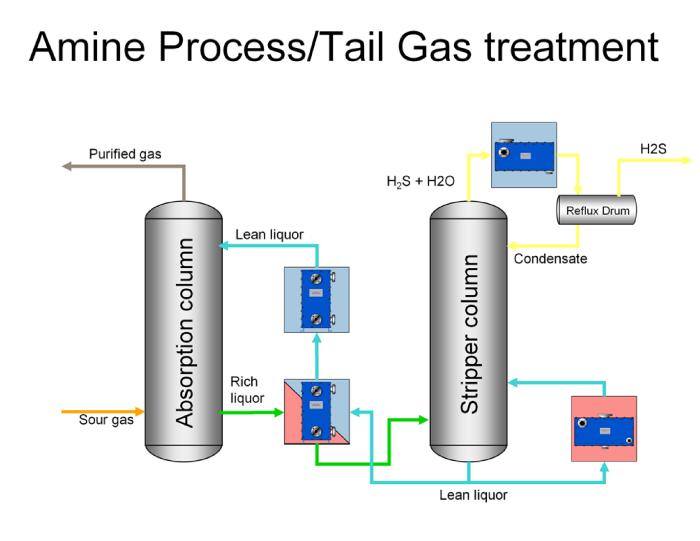

Optimizing amine process/tail gas treatment

To get the most out of your amine gas treating processes, Alfa Laval can lend our expertise, proven technology and broad range of services to help refineries save energy, reduce maintenance requirement, increase efficiency and minimize cost.

Energy efficiency in amine gas treating processes

Energy is recovered in the amine recovery section, where rich amine is preheated before the regenerator by means of lean amine, leaving the regenerator. The more energy recovered in this service, the less energy needs to be provided to the regenerator reboiler in terms of steam.

Alfa Laval Compabloc heat exchangers can be designed with a temperature approach of as little as 5°C. This maximizes energy recovery, thereby minimizing steam consumption in the reboiler.

The regenerator reboiler is often designed as a kettle type reboiler. These typically require a large temperature difference between the boiling media and the steam. This means that a higher pressure steam is required to run the reboiler.

When Alfa Laval Compabloc heat exchangers are used as rising film thermosiphon reboilers for the amine regenerator column, a temperature difference of less than 10°C is possible to initiate boiling and create natural circulation through the reboiler. This often means that it is possible to use more readily available low-pressure steam instead of medium-pressure steam.

Mitigating fouling in amine process/tail gas treatment

Depending upon the process gas being treated, the heat recovery service can suffer from varying degrees of fouling. There are different types of fouling deposits. Fouling can take form as corrosion particles that typically come from the regeneration tower, or as sludge from the absoprtion tower when there are process upsets and hydrocarbon carry-over into this column. Fouling tendencies also increase when heat stable salts are not continuously removed from amine solution. To minimize fouling tendencies, Alfa Laval Compabloc heat exchangers are designed for maximum shear stress and turbulence in the heat transfer channels, which greatly reduce the fouling tendency of the exchanger.

Improving corrosion resistance

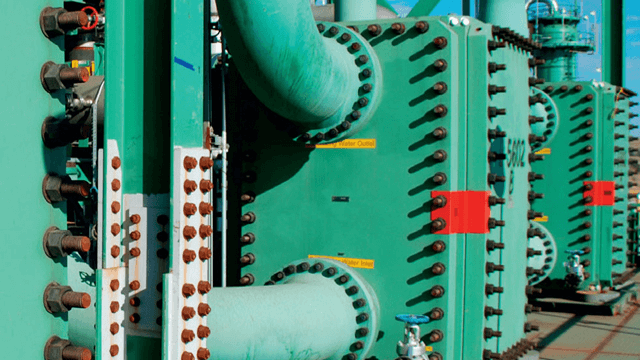

If there is a high content of hydrogen sulfide in the gas treated, the risk of corrosion in the amine recovery process equipment also increases. In many cases, carbon steel material cannot be used, and the use of a higher grade of material is required. Standard Alfa Laval Compabloc heat exchangers are made of AISI 316L stainless steel. Moreover, higher grades of material are readily available upon request.

Safeguarding processes through reliable, leak-proof design

Because hydrogen sulfide is a lethal compound, the risk of leakage from heat exchangers handling this media must be minimized. Alfa Laval Compabloc heat exchangers have plate packs that are laser-welded to form heat transfer channels. Because there are no inter-plate gaskets sealing the heat transfer channels to the environment, the risk of external leakage is minimized.

Reducing amine costs

The amine used for process and tail gas treatment is often a proprietary compound. As such, its cost can represent a hefty investment when considering the total cost of the process unit.

When Alfa Laval compact heat exchangers are used in the process, the hold-up volume of the exchangers is minimized, reducing the complete amine inventory by up to 20%. In addition, due to the short hold-up time of amine in a Compabloc rising film thermosiphon reboiler, the degradation of amine is limited and less makeup amine is required. This is even more true in cases where the operating temperature of the regenerator reboiler can be reduced by operating it with lower-pressure steam.

CAPEX savings for amine process/tail gas treatment

Heat exchanger costs also represent a large percentage of the total process unit cost. This is especially true if several large traditional shell-and-tube heat exchangers in series are required to maximize energy efficiency or when the use of high-grade material for large shell-and-tube heat exchangers or kettle type reboilers is required.

Using high-efficiency Alfa Laval heat exchangers instead of shell-and-tube units can reduce the heat transfer area by up to three times and will also minimize the number of heat exchangers required. This increases cost-efficiency, especially when high-grade material is required. Further cost reductions are resulting when installation costs are included, and when installation on construction, such as for overhead condensing services, are required.

Proven technology for amine process/tail gas treatment

Alfa Laval has close to 300 compact heat exchangers operating as interchangers, reboilers, condensers and coolers in amine treatment units in crude oil refineries around the world. These units provide refineries with maximum efficiency and uptime while minimizing fouling and corrosion tendencies.