Coldblock - challenges and solutions

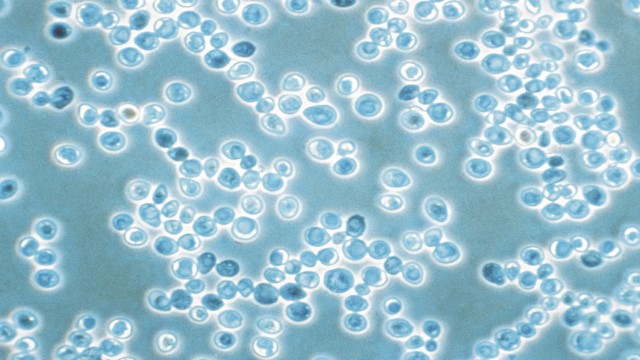

Management and fermentation of yeasts.

Yeast management and fermentation are essential parts of the cold section. Equipment to prevent contamination and ensure high yeast viability is essential for a consistent, reliable and effective fermentation process.

Challenges

- High cost

- Reliance on commercial yeast strains

- Limited opportunity for creativity

Solutions

- Alfa Laval 3-in-1 yeast module, or

- Alfa Laval yeast propagation plant

Results

- Ability to rehydrate, propagate and reuse yeast

- Fully customizable solution

Challenge

- Inconsistent or slow fermentation profile

Solution

Results

- Improves homogenization during fermentation

- Optimized performance of alcohol extract

- Flexibility: mobile unit that can be moved between tanks

Challenges

- Long duration of sedimentation

- Big waste of beer

- Great turbidity

- Low performance

- Need to increase production capacity

Results

- Higher production capacity due to clarification speed without the need to expand fermentation capacity

- Beer recovery up to 15% compared to drain

- Possibility of clarifying the beer when the profile is correct

- Long shelf life without haze defects (especially important for exports)

- Rapid emptying of the separators also translates into increased tank rotation, providing more capacity without further investment

- An average 3% increase in performance between the fermentation vessel and the beer tank based on operating procedures

- Up to 8% performance improvement in low to medium flocculating yeast strains

Dry hopping

Hops drying is the process of adding hops after fermentation to add more aroma to the beer. Traditionally, drying hops is done in beer styles such as pale ales and IPAs, but it is also used in brewing other styles of beer.

Challenge

- Slow process and loss of beer

Solutions

Alfa Laval hop drying equipment:

Results

- Maximizing the use of hops

- Acceleration of the dry hopping process

- Homogenization of beer streams to improve downstream hop removal by centrifugation